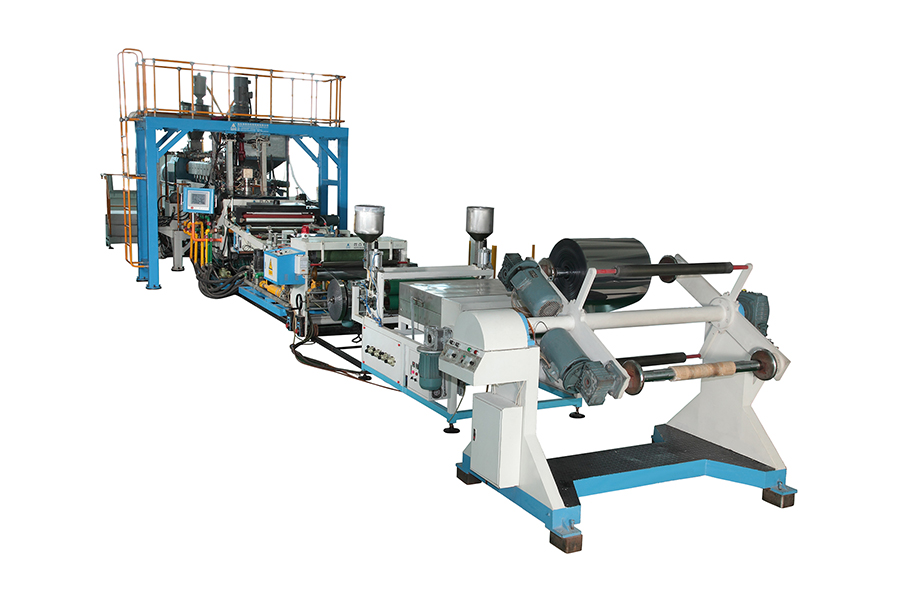

Twin Screw Plastic Extruder (PET Sheet Extrusion)

Technical Parameter

WJP(PET)75B-1000 Twin Screw Plastic Extruder (PET Sheet Extrusion)

| Applicative materials | Screw specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | kg/h | kW | |

| APET,PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Features

1.The screw element adopts conjugate type double thread screw with computer optimization design and precision machining. Besides, the screw is designed with multivariate combination modular construction, which has superior self-cleaning and interchangeability.

2. Based on years of screw configuration design experience, AUTO can perform optimal configuration of screw elements combination with the help of software technology. Therefore, it can realize transmission of plasticizing materials, mixed refining, shearing and dispersion, homogenization, volatilization and devolatilization, keep pressure and extrusion and other functions according to customer’s materials and processing technology.

3. The machine barrel is designed with two vacuum exhausting connectors ensuring fully discharging of water vapor and other volatile gases.

4. The twin screw plastic extruder is designed with melt dosing pump ensuring quantitative output with steady pressure, which can also help realize automatic closed-loop control of pressure and speed.

5. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.

Advantage

One of the main highlights of our twin screw plastic extruders are their screw elements. Great care has been taken to ensure maximum efficiency and durability by employing a conjugated twin-flight screw. This unique design is combined with computer optimization technology and precision machining, resulting in superior performance. The screw elements also feature a modular construction for superior self-cleaning and interchangeability. This ensures a smooth and uninterrupted production process, minimizing downtime and maximizing productivity.

Years of experience in screw configuration design allows us to further optimize the performance of the extruder. With the aid of cutting-edge software technology, we can optimally configure screw element combinations. This means our extruders can efficiently transfer and plasticize material, guaranteeing a consistent high quality output. Our software technology plays a vital role in achieving optimal operating conditions, ensuring our customers are able to produce the highest standard of PET sheet.

Another significant advantage of our twin screw plastic extruders is their versatility. Whether you are producing PET sheet for packaging, thermoforming or any other application, our extruders can meet your unique needs. It is capable of processing a wide variety of materials, providing greater flexibility in your production process. Additionally, our extruders are designed for easy and quick adjustments, allowing you to easily switch between different product formats. This versatility saves you time and money, making our extruders a cost-effective solution for your PET sheet extrusion needs.