Six Axis Robot

Pulp Molding Machine

Biodegradable Tableware Machine

Disposable Bagasse Sugarcane Fiber Paper Pulp Tableware Machine

Paper Pulp Meal Box Making Machine

Full Automatic Paper Pulp Plate Making Machine

|

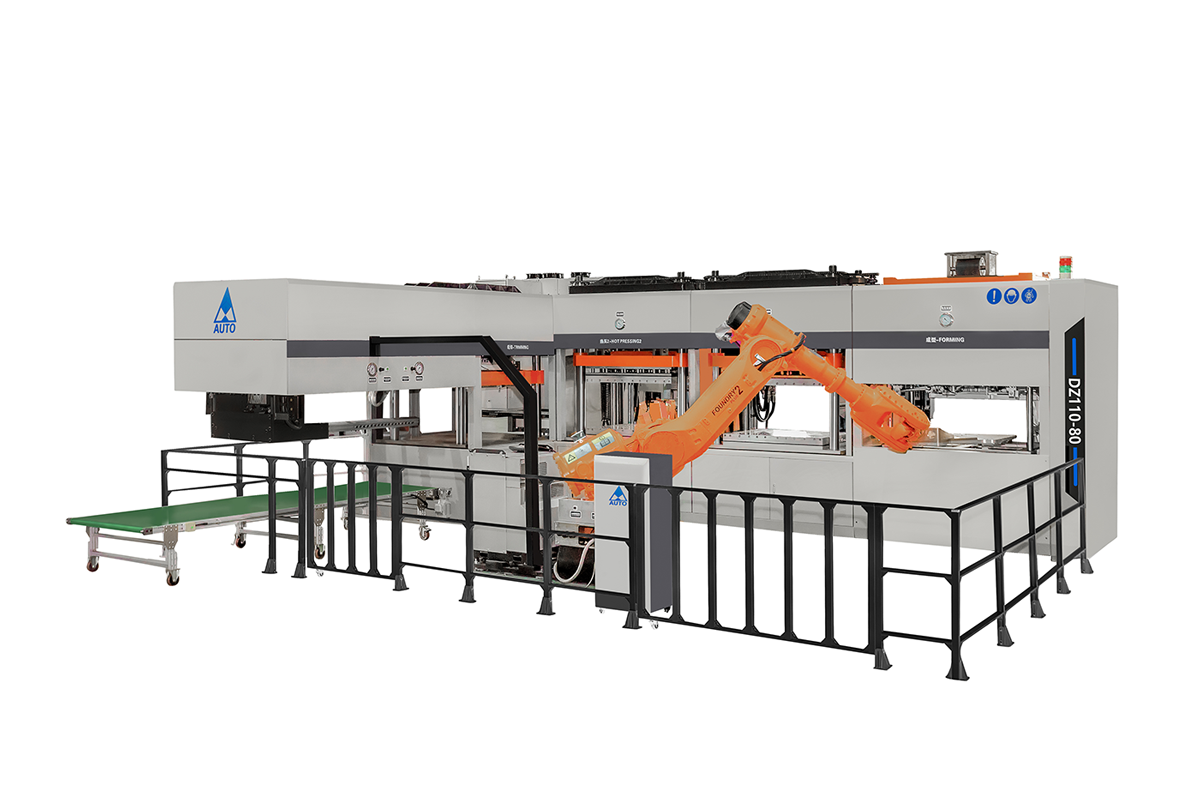

Model |

6-axis robot |

|

Forming type |

Reciprocating forming |

|

Formning size |

1100mm x 800mm |

|

Max. Forming depth |

100mm |

|

Heating type |

(192kw) Electricity |

|

Max. Press pressure |

60 ton |

|

Max. trimming pressure |

50 ton |

|

Power consumption |

65-80kw·h Depend on the product shape |

|

Air consumption |

0.5m³/min |

|

Vacuum consumption |

8-12m³/min |

| Capacity | 800-1400kg/day Depends on product design |

|

Weight |

≈29ton |

|

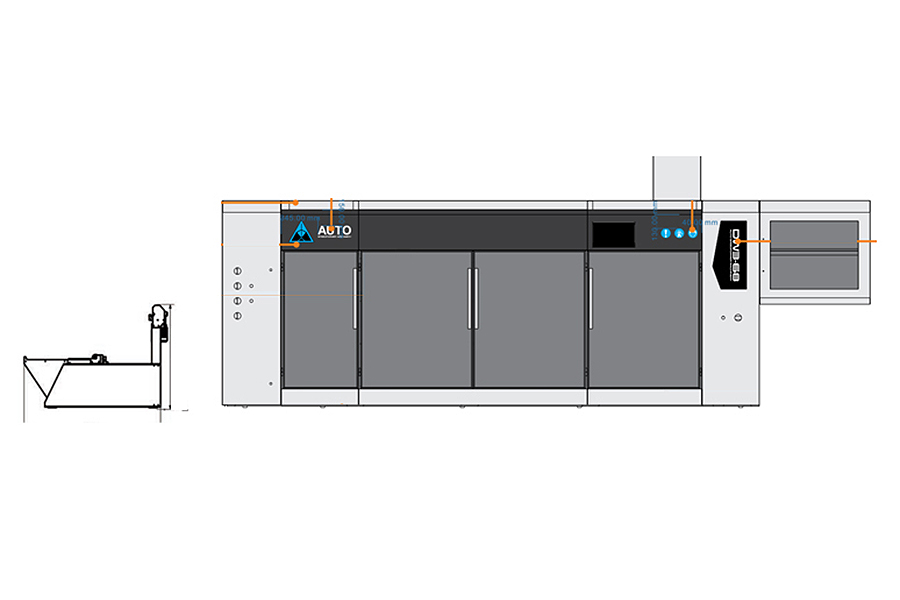

Machine dimension |

7.5m X 5.3m X 2.9m |

|

Rated power |

251kw |

|

Production speed |

2.7cycle/min |

♦ Disposable Tableware

♦ Paper Plates And Bowls

♦ Fast Food Take-away Box and Lid

♦ Ready Meal Packaging Trays

♦ Supermarket Fresh Trays

♦ Branded Food Packaging

♦ Cup and Lid

♦ Cup Holder and Carriers

1)Intelligent HMI control system, fully closed-loop production.

2)Perfect fault protection function: automatic pause and alarm when a certain link fails.

3)One-key to run production mode.

4)Servo control of the whole machine, high production capacity, low energy consumption, energy saving of more than 50% and capacity increase of more than 60%.

5)B&R temperature control: zone control, energy saving, zone heating in 15 zones up and down, set the different temperature according to the products’ depth.

6)The whole machine is equipped with memory and data storage functions (formula storage and direct transfer for mold change). It can be enabled with one key and directly enter production.

7)Automatic lubrication system(automatic timing oil supply)

8)Ductile iron castings of the working platform (high strength and certain toughness)

9)The whole machine is waterproof and anti-corrosion

10)Unique and innovative hot pressing process, large discharge steam exhaust pipe system, zoned temperature control to ensure uniform heating of each part in cavities

11)Convenient mold loading and unloading function, humanized mold positioning device, greatly improving the efficiency of loading and unloading molds.

12)The trimming station is equipped with a general air plate and a general stripping cylinder, which greatly reduces the production cost of the cutting mould.

13)The innovative hanging manipulator completes the automatic recycling of edge materials and the stacking counting of products.