Multi-Layer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)

Technical Parameter

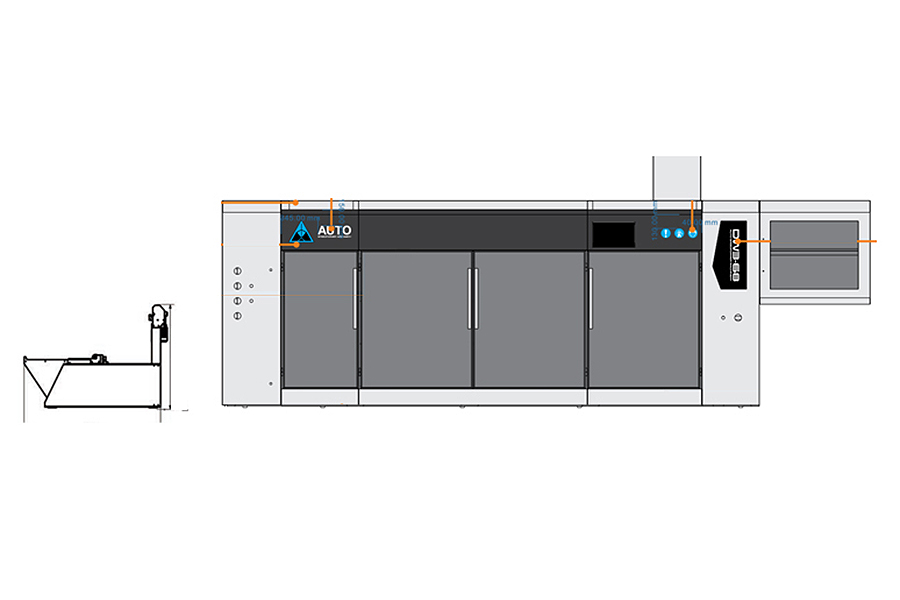

WSJP120/90/65-1000 Multi-Layer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)

| Layer number | Screw specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | kg/h | kW | |

| < 5 | Φ120/Φ90/Φ65 | 0.2-2.0 | ≤880 | 300-800 | 380 |

Feature

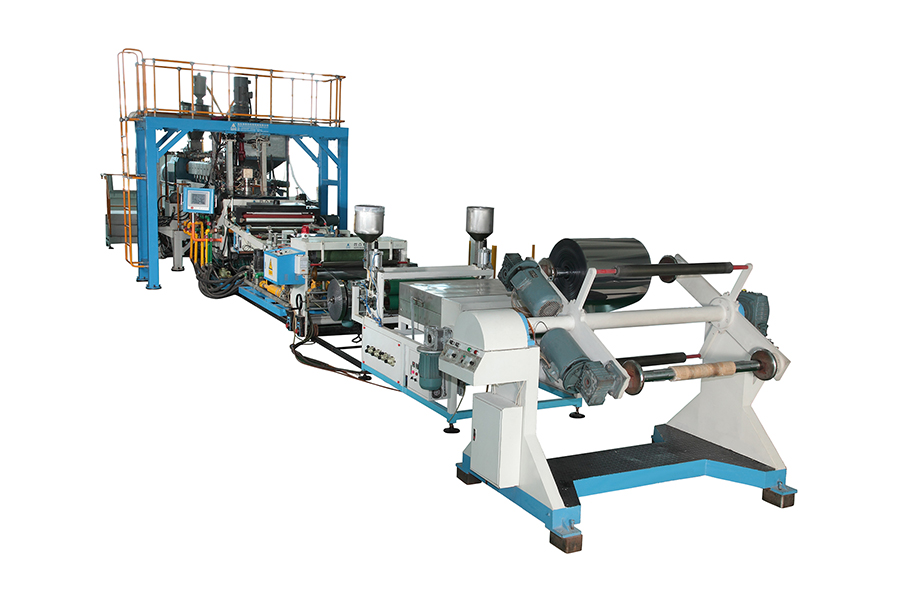

1. The single screw plastic extruder in the manufacturing line adopts new type of screw structure featured as stable feeding and uniform fusion mixing, which can reduce energy consumption and increase production output.

2. The plastic extruder adopts directly connection between motor and reduction gears, which can improve transmission efficiency and reduce speed fluctuation ensuring the stability of extrusion.

3. The extruder is designed with the melt dosing pump and it can be cooperated with precise multi-layer distributor. The flow proportion and blade clearance ratio are all adjustable, which can lead to more uniform plastic sheet layer.

4. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.

Advantage

At the heart of this innovation lies our newly designed single-screw plastic extruder. Its unique screw configuration ensures stable feeding and uniform melt mixing, resulting in superior product quality. This innovative feature not only reduces energy consumption, but also significantly increases output. With our multi-layer plastic extruders, you can now achieve higher productivity without compromising product quality and consistency.

Another noteworthy feature is the direct connection between the motor and the reduction gear. This direct connection improves transmission efficiency and reduces speed fluctuations, ensuring a stable extrusion process. By eliminating unwanted fluctuations, our multilayer plastic extruders guarantee consistent performance, minimizing downtime and maximizing productivity. Witness a seamless, uninterrupted extrusion process like never before.

To further improve operating efficiency, our multi-layer plastic extruders are equipped with well-designed melt metering pumps. This smart addition works seamlessly with the precision balancing system to optimize material distribution and minimize waste. Say goodbye to material overuse and hello to cost-effective production.

The versatility of our multilayer plastic extruders is limitless. The machine is capable of processing a wide variety of plastic materials including PP, PS, HIPS and PE to meet different manufacturing requirements. Whether you're producing packaging materials, building components or automotive parts, our multilayer plastic extruders ensure outstanding results every time.