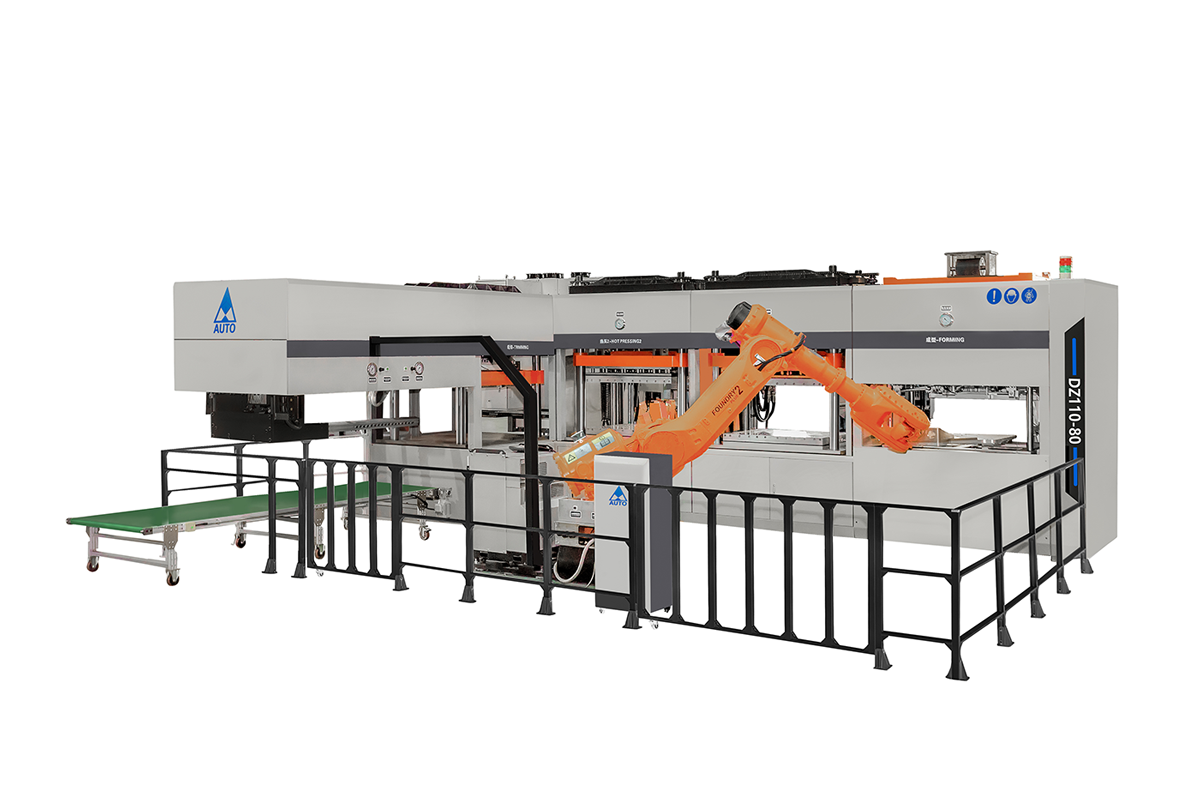

DZ130-110 Full automatic servo control fiber pulp molding thermoforming machine

Bagasse pulp mold machine, eco-friendly tableware making machine, paper lunch box production line.

| Model | 3-axis gantry manipulator |

| Forming type | Reciprocating forming |

| Formning size | 1300mm x 1100mm |

| Max. Forming depth | 120mm |

| Heating type | Electricity(208kw) |

| Max. Press pressure | 80 ton |

| Max. trimming pressure | 80 ton |

| Power consumption | 90-130kw·h Depend on the product shape |

| Air consumption | 0.5m³/min |

| Vacuum consumption | 8-12m³/min |

| Capacity | 1200-2400kg/day Depends on product design |

| Weight | ≈39ton |

| Machine dimension | 9.3m X 6.2m X 4.6m |

| Rated power | 274kw |

| Production speed | 2.5 - 2.8 cycle/min |

Multiple Applications in Eco-Friendly Molded Fiber Packaging

♦ Disposable Tableware

♦ Fast Food Take-away Box and Lid

♦ Fruit Trays

♦ Industrial package

♦ High-end Packaging

♦ Cups, Lids, Cup Holder and Carriers

1)Intelligent HMI control system, complete fault protection function, and one-key operation of complete machine production process.

2)High production capacity, Low energy consumption, Energy saving of more than 50% and capacity increase of more than 50%.

3)Intelligent temperature control: zone control, energy saving, zone heating in 16 zones up and down, set the different temperature according to the products’ depth.

4)Automatic lubrication system

5)High-strength customized steel tube fuselage, waterproof and anti-corrosion

6)Unique and innovative hot pressing process, large discharge steam exhaust pipe system, zoned temperature control to ensure uniform heating of each part in cavities

7)Convenient mold loading and unloading function, greatly improving the efficiency of loading and unloading molds

8)The trimming station is equipped with a general air plate and a general stripping cylinder, which greatly reduces the production cost of the cutting mould.

9)The innovative hanging manipulator completes the automatic recycling of edge materials and the stacking counting of products.

One of the key features of the DZ130-110 is its precise temperature control, which allows for consistent and high-quality molding of fiber pulp products. This level of precision ensures that every product meets the highest standards of quality and durability.

In addition, the DZ130-110 offers an impressive production speed with a cycle rate of 2.5 cycles per minute. This high efficiency increases output and productivity, making it ideal for businesses looking to streamline their production processes.

Additionally, the DZ130-110 is designed to use resources efficiently. The machine's air consumption is only 0.5 cubic meters per minute, minimizing waste and reducing energy costs. In addition, its power consumption range is 90-130kw·h, making it an environmentally friendly and cost-effective choice for enterprises.

Overall, the DZ130-110 fully automatic servo-controlled fiber pulp molding thermoforming machine is a top-notch solution for companies in need of reliable, high-performance production equipment. Its servo control system, precise temperature control, fast production speeds and efficient resource consumption make it a valuable asset for businesses looking to improve productivity and quality standards.

Whether you are in the packaging, food service or industrial products industry, the DZ130-110 is the perfect choice for producing a variety of fiber pulp products. Its versatility, efficiency and reliability ensure you can meet your customers' needs while maintaining a strong focus on sustainability and cost-effectiveness.