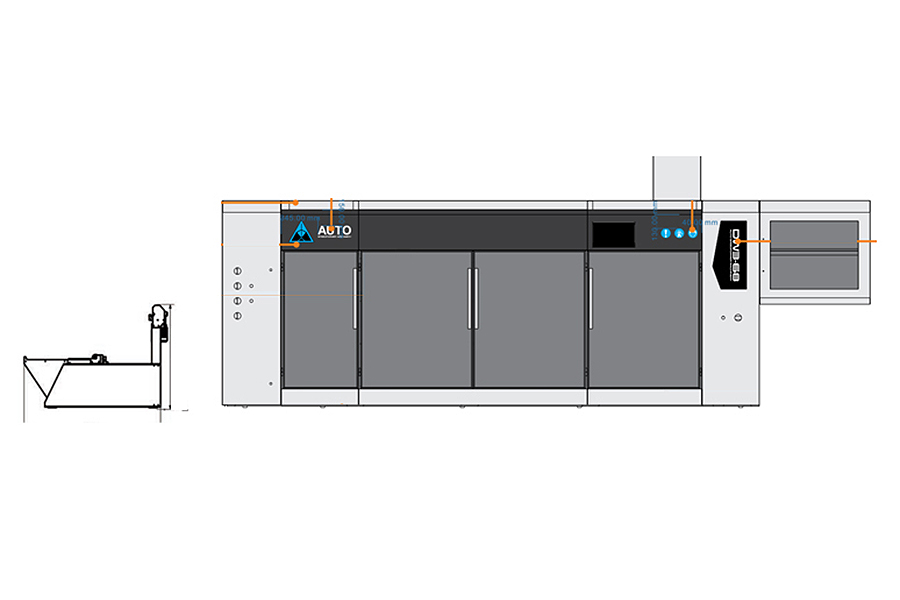

DW4-78 4-Station High Speed Thermoforming Machine

One of the main features of DW4-78 is that it is compatible with a variety of materials, including PP, PS, OPS, PET, PVC, PE, PLA, etc. This makes it a highly adaptable option for manufacturers working with different types of plastics. In addition, the machine is particularly suitable for producing perforated plastic packaging products such as fruit containers, flower pots and plastic lids. This level of versatility enables you to expand your product range and meet your customers' specific needs.

In addition to its primary function as a thermoforming machine, the DW4-78 can also be used to manufacture a variety of plastic products. This includes everything from trays and flip-tops to disposable cups and lids. The possibilities are endless, making this machine a valuable investment for any business in the plastic packaging industry.

But the benefits don't stop there. The DW4-78 is designed with high-speed production in mind, ensuring you can meet demanding deadlines and keep up with market demands. Its efficient operation and precise forming capabilities make it a valuable asset to any manufacturing facility.

Not only is the DW4-78 a high-performance machine, it also has a user-friendly design that makes it easy to operate and maintain. This means you can keep production running smoothly without unnecessary downtime or complications.

| Maximum forming area | 800×600 | mm |

| Minimum forming area | 375×270 | mm |

| Maximum tool size | 780×580 | mm |

| Suitable sheet thickness | 0.1-2.5 | mm |

| Forming depth | ≤±150 | mm |

| Work efficiency | ≤50 | pcs/min |

| Maximum air consumption | 5000-6000 | L/min |

| Heating power | 134 | kW |

| Dimension of machine | 16L×2.45W×3.05H | m |

| Total weight | 20 | T |

| Rated power | 208 | kW |

1. The DW series high speed thermoforming machine has high manufacturing, which can be up to 50 cycles per minute at most.

2. Due to advanced automatic system, absolute value servo control system and operation interface of number axis aided parameter display for controlling, the series of thermoforming machine shows superior performance for processing PP, PS, OPS, PE, PVC, APET, CPET, etc.

3. According to ergonomic principle, we design a simple mould replacing system, which can shorten the mould replacing time.

4. The cooperation between cutting type of steel blade and design of stacking equipment can improve manufacturing speed and ensure maximum production area.

5. Advanced heating system adopts new temperature control module with short response time can increase efficiency and reduce energy consumption.

6. The series of DW thermoforming machine has low noise at working and has high reliability, which is very convenient for maintenance and operation.