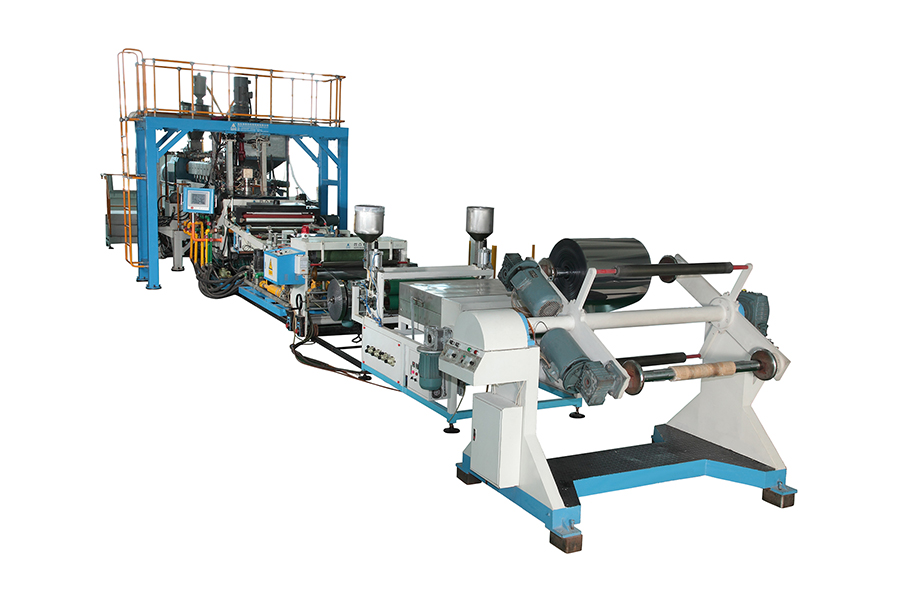

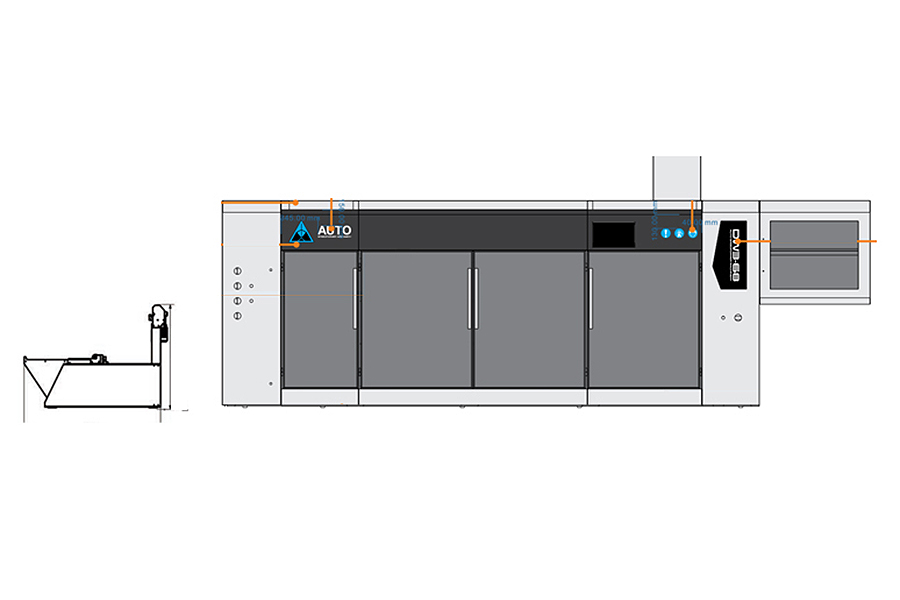

DW3-90 Three station Thermoforming Machine

| Model | DW3-90 |

| Suitable Material | PP, PS, PET, PVC, BOPS, PLA, PBAT, etc. |

| Sheet Width | 390-940mm |

| Thickness of Sheet | 0.16-2.0mm |

| Max. Formed Area | 900×800mm |

| Min. Formed Area | 350×400mm |

| Availability Punching Area(Max) | 880×780mm |

| Positive formed part height | 150mm |

| Negative formed part height | 150mm |

| Dry-running speed | ≤50pcs/min |

| Max production speed(depends on the product material, design, mould set design) | ≤40pcs/min |

| Heating Power | 208kw |

| Main Motor power | 7.34kw |

| Winding Diameter(Max) | Φ1000mm |

| Suitable Power | 380V, 50Hz |

| Air Pressure | 0.6-0.8Mpa |

| Air Consumption | 5000-6000L/min |

| Water Consumption | 45-55L/min |

| Machine Weight | 26000kg |

| Whole Unit Dimension | 19m×3m×3.3m |

| Used Power | 180kw |

| Installed Power | 284kw |

1. High speed, low noise, high reliability, and convenience to maintainance.

2. Max. production speed up to 40 cycles/minute

3. Though the structure is complex, it is still easy to operate and shows high reliability.

4. Servo-control system is applied to all the machines. Moreover, the advanced automatic system is also adopted.

5. According to material shrinkage different, there are 5 ports motorized chain track spreading adjustment to protect the chain track lifetime.

6. Machine equipped with two lubrication pumps to cover every joint of the machine working station and the chain track. They will start automatically once the machine is at auto work. This can dramatically increase the lifespan of machine.

With a maximum production speed of up to 40 cycles per minute, the DW3-90 Three Station Thermoforming Machine stands out from the competition. Its exceptional speed allows for increased output and reduces downtime, leading to improved profitability for your business. Whether you are producing large quantities or working with tight deadlines, this machine will exceed your expectations.

Despite its complex structure, the DW3-90 Three Station Thermoforming Machine remains incredibly user-friendly and easy to operate. We understand that efficiency is paramount in any production environment, which is why we have ensured that this machine is intuitive and simple to use. Your operators will be able to quickly understand and deliver consistent results, guaranteeing a smooth workflow.

In addition to its ease of use, this machine demonstrates unmatched reliability. We have incorporated a servo-control system into all the machines, ensuring precise control and consistent performance. This advanced technology allows for seamless operation, reducing the risk of errors and minimizing waste. Moreover, the adoption of an advanced automatic system further enhances the overall reliability of the machine, making it a valuable asset for your production line.

We understand that the durability of your equipment is crucial for long-term success. Hence, the DW3-90 Three Station Thermoforming Machine is equipped with 5 ports motorized chain track spreading adjustment. This feature protects the chain track's lifetime by adjusting to different material shrinkages. As a result, your machine will have a longer lifespan, ensuring long-term profitability and reducing maintenance costs.