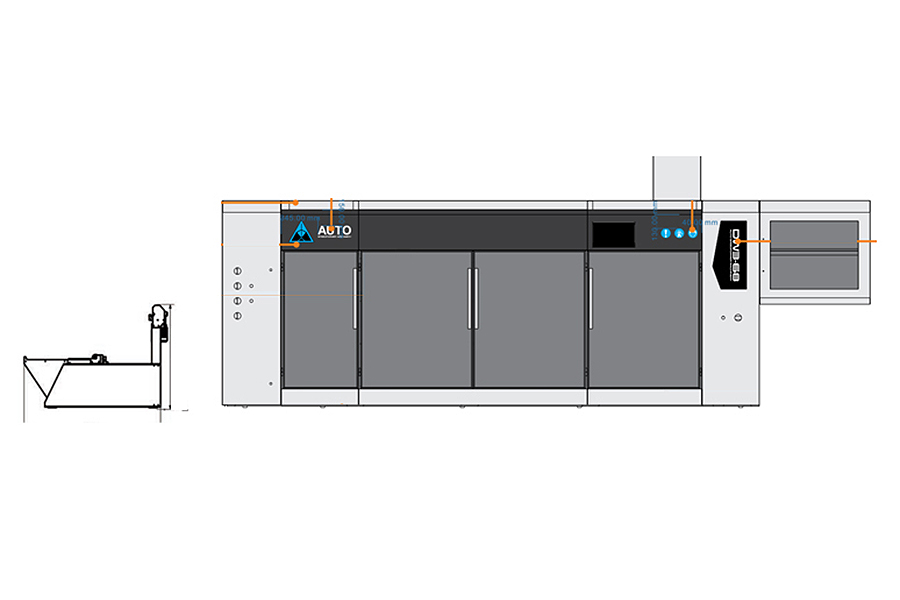

DW3-66 Three Station Vacuum Thermforming Machine

| Model | DW3-66 |

| Suitable Material | PP,PS,PET,PVC |

| Sheet Width | 340-710mm |

| Thickness of Sheet | 0.16-2.0mm |

| Max. Formed Area | 680×340mm |

| Min. Formed Area | 360×170mm |

| Availability Punching Area(Max) | 670×330mm |

| Positive formed part height | 100mm |

| Negative formed part height | 100mm |

| Work Efficiency | ≤30pcs/min |

| Heating Power | 60kw |

| Station servo motor | 2.9kw |

| Winding Diameter(Max) | Φ800mm |

| Suitable Power | 380V, 50Hz |

| Air Pressure | 0.6-0.8Mpa |

| Air Consumption | 4500-5000L/min |

| Water Consumption | 20-25L/min |

| Machine Weight | 6000kg |

| Dimension | 11m × 2.1m × 2.5m |

| Used Power | 45kw |

| Installed Power | 75kw |

1. DW is widely applicated in produce plastic blisters package, like trays, food containers, hinged boxes, bowls, lids, which show the highest flexibility of our DW3-66 vacuum forming machine.

2. Its forming area which suitable for trial order quantity production, easy change the mould set, and customized mould tools.

3. Twin side heating oven design for lots of common plastic material application.

4. Thermal Protector for each servo motor, in case of overworking from damaging equipment. And overcurrenct protector for each motor.

One of the key features of the DW3-66 is its spacious forming area, which is ideally suited for trial order quantity production. This allows businesses to efficiently test their product designs without committing to large-scale production runs. Additionally, the machine boasts the ability to easily change the mold set, enabling quick and effortless customization of mold tools.

A unique design element of the DW3-66 is its twin-side heating oven, which allows for superior heating distribution. This design ensures consistent and quality results across a wide range of common plastic materials, making it the go-to choice for businesses working with various types of plastics.

To guarantee the durability and longevity of this state-of-the-art machine, the DW3-66 is equipped with a thermal protector for each servo motor. This acts as a fail-safe in case of excessive working conditions, preventing any damage to the equipment. This feature not only protects the investment businesses make in the machine but also ensures the safety of operators.

With the DW3-66, businesses can achieve unmatched efficiency and productivity. The machine combines high-speed operation with precise control, resulting in rapid production cycles without compromising on quality. The vacuum forming process is seamlessly integrated into the machine's operation, allowing for the creation of complex shapes with ease.

Furthermore, the DW3-66 offers fully programmable control, allowing businesses to automate processes and optimize production. This not only saves time and effort but also minimizes the risk of human error, ensuring consistently excellent results.