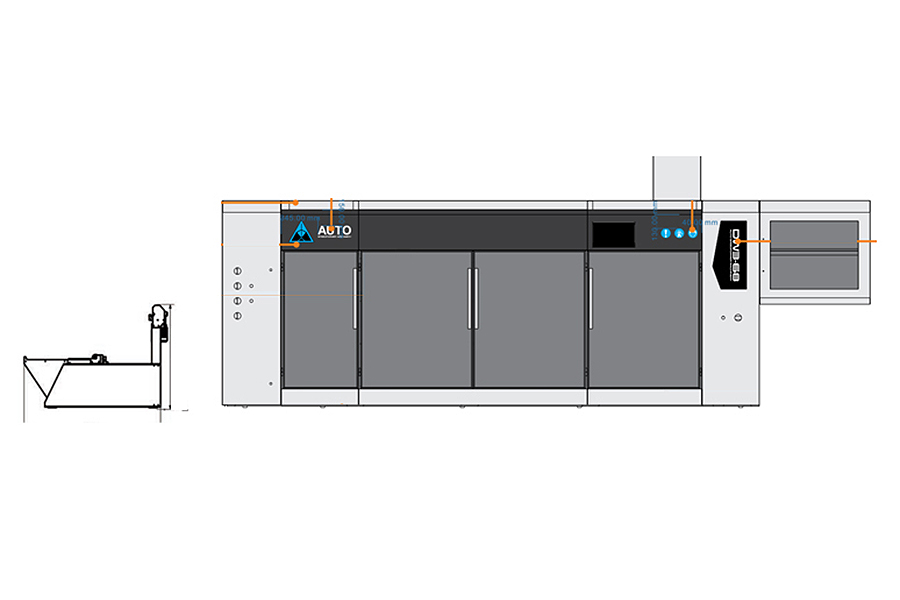

ZB80-50 Cup Thermoforming Machine

|

Model |

DC8050 |

|

Suitable Material |

PP, PS, PET, PE, starch based materials |

|

Sheet Width |

390-850mm |

|

Thickness of Sheet |

0.16-2.0mm |

|

Max. Formed Area |

800×550mm |

|

Formed part height |

≤180mm |

|

Production speed(depends on the product material, design, mould set design) |

15-30pcs/min |

|

Main Motor power |

20kw |

|

Winding Diameter(Max) |

Φ1000mm |

|

Suitable Power |

380V, 50Hz |

|

Air Pressure |

0.6-0.8Mpa |

|

Machine Weight |

About8000kg |

|

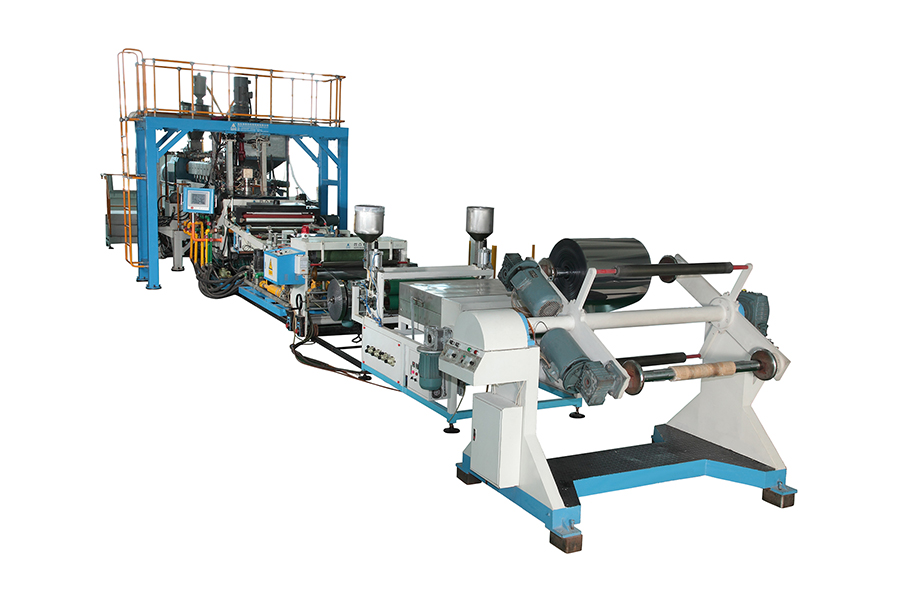

Whole Unit Dimension |

8.5m × 2.2m × 3m |

|

Used Power |

110kw |

|

Installed Power |

185kw |

1.DC8050 model is widely applicated in produce plastic blisters package, like cups, bowls trays, food containers, hinged boxes, lids, which show the highest flexibility of our cup making machine.

2.DC8050 full servo thermoforming machine is the popular product that our company has absorbed and digested the advanced technology at home and abroad in recent years, and has come to the fore through self-designed and breakthrough tests.

3.The clamping and plug assist mechanism adopts the patented structure in China, which has the advantages of stable operation, improved clamping speed, reduced noise and reduced power consumption.

4.It can be directly used in starch based materials production.

5.Machine adopt the manipulator to finish the counting and stacking function. It make the production tidy and neat.

Our DC8050 model is designed for the production of a wide variety of plastic blister packaging such as cups, bowls, trays, food containers, hinged boxes and lids. With its exceptional versatility, this cup maker meets the needs of a variety of industries including food packaging, medical supplies and consumer goods.

What sets our DC8050 model apart is its integrated full servo technology. We carefully absorb and digest advanced technologies from domestic and foreign markets to ensure that our products are always at the forefront of the industry.

One of the highlights of our cup thermoforming machines is the clamping and plug assist mechanism, which employs our patented strategy. This innovation allows for precise and efficient operations, ensuring that each product is perfectly formed and in perfect shape. Say goodbye to irregularities and imperfections in plastic blister packs.

Additionally, our machines boast a user-friendly interface that allows seamless operation by even those with minimal technical expertise. With just a few clicks, you can easily set the parameters you want and let the DC8050 do its magic. Additionally, our advanced control systems guarantee consistent and reliable performance, increasing productivity and minimizing downtime.

In a fast-paced and ever-evolving industry, we understand the importance of sustainability and environmental responsibility. That's why the DC8050 cup thermoformer has energy saving features that reduce power consumption without compromising productivity. By investing in our machines, you not only increase the efficiency of your operations, but also contribute to the protection of our planet.